Services

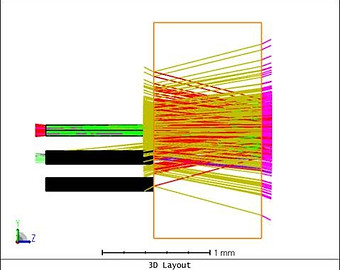

Optical Fiber Lensing and Cleaving - CO2 ablated

OFP has pioneered the use of computer controlled rapid laser ablation technologies to precision shape the tips of fibers with "cleave facets," or miniature lens features on the fiber core. These ablated features are designed to exactly match with our customers' emitters and detectors to provide direct high efficiency coupling solutions.

OFP can custom shape wedge (CLF) lenses, conical lenses and ablated cleaves from 90 degree to 50 degree angles.

Key Features

-

Cleave angle from 0 to 50 degrees

-

Angular tolerance < +/- 1 degree

-

Super smooth ideal cleave surface

-

For both single or multi-fiber assemblies

-

Any fiber type (SMF, MMF, PM)

-

Conic and CLF (Wedge) lenses

-

Customized lens shaping for optimal coupling power

-

Optical coating available from OFP

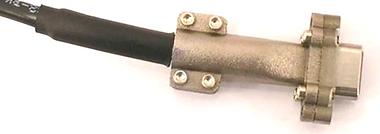

Pressure Testing Services -

Hydraulic, He, N2

Optical Fiber Packaging (OFP) offers multiple pressure testing services to check the hermeticity of seals, feedthroughs, penetrators, and more. OFP has a diverse range of equipment to be able to test parts from 0 to 40,000 psi, as well as conduct helium leak tests at both vacuum and high pressure environments.

We have multiple types of chambers which allows us to test many types of assemblies (both small and larger ones) at a broad range of pressures.

Key Features

-

Vacuum Helium Leak Testing (0-1 bar)

-

High Pressure Helium Leak Testing (up to 100 bar)

-

High Pressure Hydraulic Testing (up to 1034 bar)

-

High Pressure Gas Testing, Nitrogen, Helium (up to 1034 bar)

-

High Pressure Hydraulic Testing (up to 2758 bar)

Qualification Services

As an extension of its design, development and manufacturing capabilities OFP are able to offer contract Qualification Services.

With a extensive range of environmental chambers, ovens, optical and mechanical test equipment, OFP can perform most key Telcordia, IEC and Mil performance and reliability test protocols in house.

The work is supported by our skilled technicians and engineers.

Key Features

-

Thermal shock

-

High temperature storage

-

Damp heat

-

Low temperature storage

-

Temperature cycling

-

Mechanical testing for integrity

-

Fiber proof testing

-

Pull, Twist, Side Load

-

Durability and Fatigue

-

Optical Coatings

Many OFP assemblies are terminated with a custom cleave or lens at the fiber tip or FVA surface. Very often, customers require the minimization of the reflection of optical beams entering or exiting the fiber assembly in order to reduce back reflection or handle high optical powers.

OFP provides bespoke multi-layer dielectric antireflective coatings for different wavelength ranges (300 nm to 2.5 um), most often around 900 nm, 1000 nm, 1300 nm or 1550 nm using our most reliable, state-of-the-art, fully automated electron beam ion assisted technology. It allows us to coat large volumes of optical fibers in each run (typically up to 300 fibers).

Key Features

-

Standard and custom optical coatings available

-

Single band (R<0.1% over ~100 nm range) and dual band (R< 0.3 % over ~300 nm range)

-

Connectorized, hermetic and specially terminated assemblies

-

From 10 pcs to 10,000 pcs batches

-

On-time delivery at competitive pricing

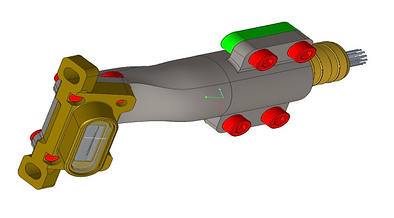

ODM Design

and Manufacture

OFP’s management and engineering teams have been working exclusively with fiber optics since the early 1980’s and have an extensive experience in the fiber optics, sensing optical science, and optoelectronics industries.

Having designed, developed, and manufactured many successful pioneering fiber products, our team is pleased to offer ODM services to its customers.

OFP’s ODM services benefit customers by limiting the resources they have to apply to new product developments. We also help to reduce time to market with all the key design, development, engineering, testing, qualification, sourcing and manufacturing expertise needed for most optical devices under one roof.

Examples of ODM Projects

-

Optical Sensor Development

-

Pressure Sensing

-

Level Sensing

-

Ice Detection

-

-

Medical Sensor Designs

-

Custom Connector Designs (UNDEX)

Research

Design and Modelling

Production